Mobile welding plant

Semi-stationary welding

Equipment

Many construction sites can be supplied faster, simpler and cheaper: standard length rails from the rolling mills are flash-welded into long rails in the immediate proximity of the work site. This combines logistical advantages with the quality of a stationary welding plant.

Advantages

Some mobile welding plant scenarios

Video

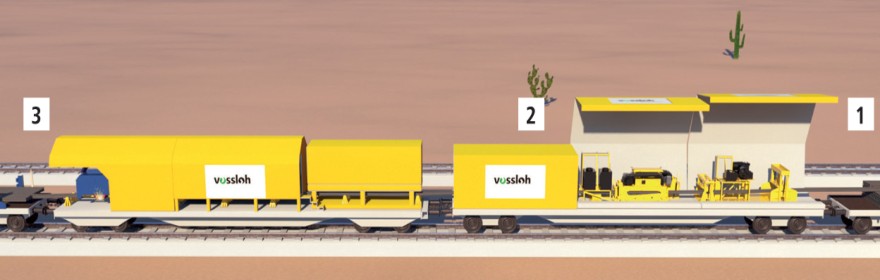

Mobile welding plant – modular construction

1 Short rail storage

Rails of up to 120 m in length are delivered on rail cars.

2 Welding unit

Here, the rails are prepared for welding and then a transport crawler positions them exactly to be welded in the welding module.

3 Final machining of the welds

This is where the welds are ground and aligned. The rails produced can be up to 400 m long.